When constructing pipelines and sanitary installations, it is essential to protect them from pipeline freezing. This protection is crucial to guarantee the durability of the pipeline and the safety of the buildings and structures through which the pipeline passes. Damage caused by pipe freezing can be extensive and expensive to repair.

What damage can freezing pipes cause?

It is very important to adequately protect pipework, especially water pipework, from freezing. This is important because water increases in volume when it freezes, an unprotected pipeline can lose its tightness or burst. This is particularly dangerous for installations installed in building partitions, where a burst pipe can damage a wall and smaller leaks can be particularly difficult to detect.

Such a damaged installation can flood nearby rooms, or lead to the building envelope or structural elements becoming wet and damp. The water-soaked material will crack when it freezes again, which can seriously weaken the building structure.

Proven ways to protect installations from freezing

The following are effective ways to protect pipelines and plumbing lines from freezing:

- Installation of an outdoor system below ground frost depth - in winter at sub-zero temperatures, the ground only freezes to a certain depth below the surface. Poland is divided into four climate zones, each with its own ground frost depth. Pipes buried in the ground are laid below ground frost depth.

- use of insulating materials - If it is not possible to route the pipeline underground or below ground frost depth, the pipeline must be protected with a layer of insulating material such as foam lagging, mineral wool lagging or polystyrene lagging, for example. Foamed polystyrene lagging 160/260 EPS 100 slate. We have already written about the types of lagging in this article.

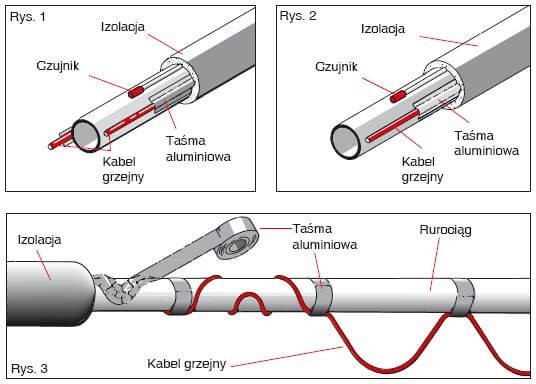

- heating cable reheating - used in situations where the thermal insulation of the pipe alone may not be sufficient. Heating cables are laid on pipes and then covered with a layer of insulation,

Fig.1. Diagram of pipe heating with heating cable

What to look for before installing pipe insulation materials?

When selecting insulation materials for pipe insulation, several criteria should be taken into account. Insulation laggings should be characterised by low thermal conductivity, non-flammability and moisture resistance.

When selecting an insulation material, it is also important to check its intended use and the permissible installation location, e.g. whether the chosen material is approved for installation in the ground.

When installing insulation material on pipes, it is worth using a top layer of reinforced aluminium foil. This provides protection against mechanical damage and additional thermal insulation.