External drains play a very important role and it is impossible to imagine the existence of any infrastructure without drains. A modern sewerage system made of the highest quality materials will ensure that it cannot be seen, heard or felt 🙂. If you want to achieve the best quality and sustainability of your investment I will help you find the right solution.

External drains - PVC pipes

Let's start with the fact that every sewer system is exposed to chemicals, changing weather conditions, pressure or corrosion. For many years, the production of sewerage systems has been based on thermoplastics, which must meet the highest requirements and be resistant to ageing processes. However, PVC is the most common. It has the advantage of being lightweight and easy to shape individual components. But that is not all! Compared to other groups of rigid materials, PVC ensures a much lower failure rate of the network . All types of sewer pipes and fittings are connected to one another via grooved sockets in which an annular elastomer seal is fitted. The smooth inner surface of the pipe ensures low flow resistance. Another advantage is the durability, which is estimated to last up to 100 years! And if you want to find out what to look out for when carrying out the installation, be sure to take a look at our article.

Solid or foamed pipes?

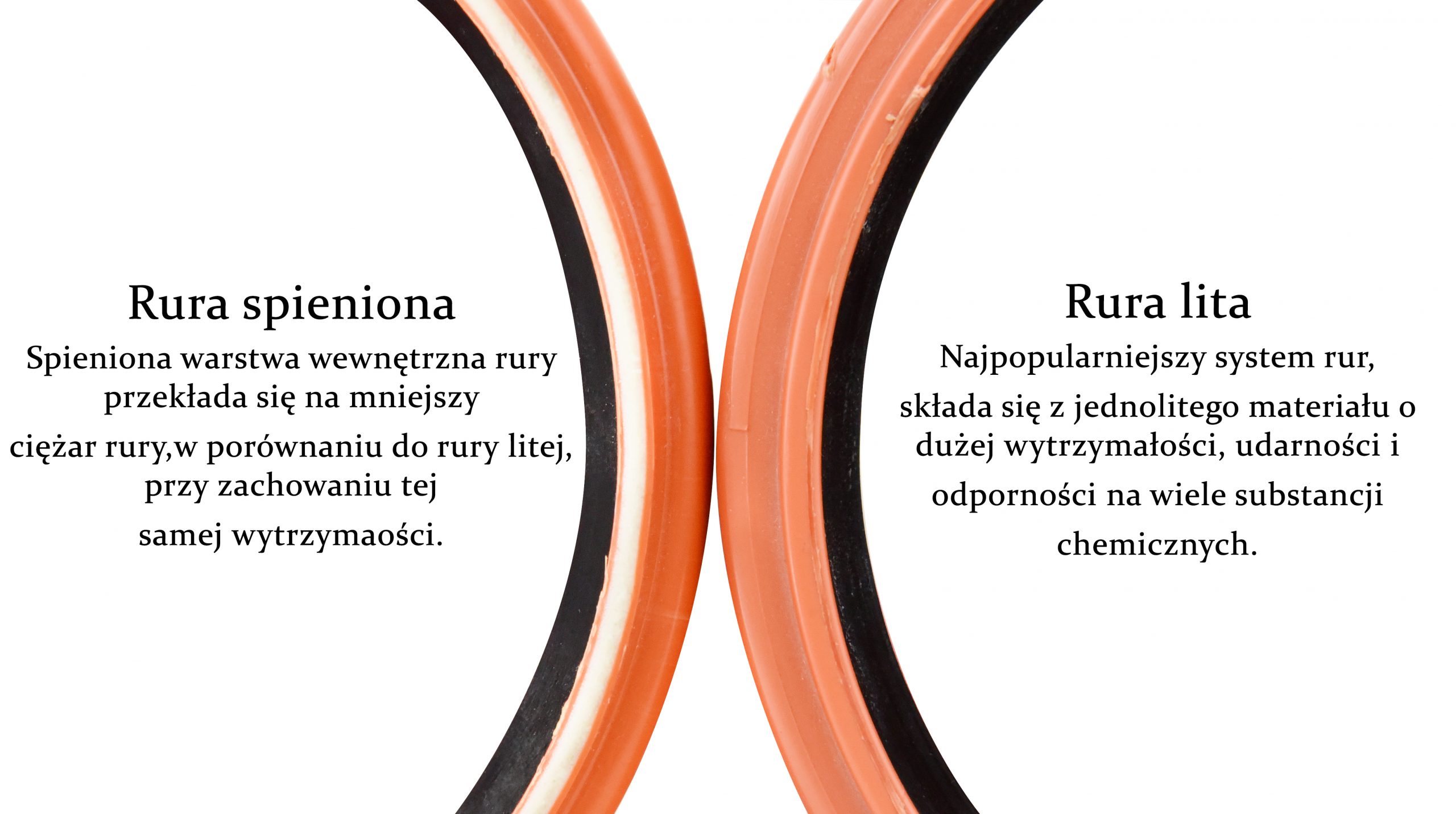

- Solid pipe - is the most common pipe and fitting system and is connected by means of a push-fit connection. It takes the form of single-layer, homogeneous pipes manufactured by extrusion in accordance with EN 1852 based on

exclusively pure polypropylene, without fillers or foaming. The entire pipe consists of a homogeneous material and the wall surface in cross-section has a uniform colour. Solid pipes can be used in domestic areas as well as under roads with heavy traffic. The thermal resistance allows the pipes to be installed at temperatures as low as -20 C and to convey wastewater at 90 C continuously.

- Foamed tube - consists of three layers, with a foamed layer between the base plastic layers. This makes the product lighter yet just as strong as solid pipes. Their production takes place in a process called coextrusion and requires the latest high-tech methods. Foamed pipes are most often used to make sewer connections for single-family homes and for the construction of utilities for investment plots of larger buildings.

Sewer pipes - stiffness classes

Undoubtedly, an important element to pay attention to is the stiffness class of the pipe . This will allow you to easily assess the pipe's resistance to unavoidable deformation, but also to determine to what depth it should be applied. Choosing a pipe with the right stiffness class allows the system to adapt to different static and dynamic loads.

So, it looks as follows :). The stiffest tubes S grades designed for installation under carriageways , can be used at depths of up to 8 m, medium stiff pipes N classes used outside the carriageway, e.g. for connections to buildings, at depths of up to 6 m, and the lightest pipes L classes applied to green areas unencumbered by vehicle traffic at a depth of 2 m.

The differences between the different stiffness classes are as follows:

If you want to avoid breakdowns in your newly built home, invest in the right design and quality components. This will ensure that your system will work flawlessly for years to come. Choose the right pipe for you and enjoy your installation for a long time.