Studnie kanalizacyjne to niezbędny element każdego systemu kanalizacyjnego. Ich funkcją jest utrzymanie sprawnego przepływu cieczy przez instalację.

W jakim celu montowane są studnie kanalizacyjne?

Studnie kanalizacyjne to powszechnie stosowany element kanalizacji. Stosuje się je w zewnętrznych systemach kanalizacji grawitacyjnej; w sanitarnych, deszczowych, drenarskich, ogólnospławnych oraz w kanalizacji przemysłowej, o czym pisaliśmy tutaj.

Studzienki umożliwiają łatwy i szybki dostęp do instalacji nie tylko w przypadku awarii, ale również podczas dokonywania przeglądów i konserwacji. Umożliwiają również przepływ wody lub ścieków.

Studzienka betonowa czy tworzywowa?

Najbardziej znanym rodzajem są studnie betonowe- używane od dziesiątek lat. Jednak w ostatnim czasie coraz bardziej popularne są studnie wykonane z tworzywa sztucznego. Budowa i materiał, z jakich konstruuje się studzienkę, zależą przede wszystkim od jej przeznaczenia.

Wyróżniamy studnie:

–złazowe (rewizyjne) – są one na tyle duże, że umożliwiają wejście do środka w celu skontrolowania instalacji lub dokonania koniecznych napraw. Tutaj doskonale sprawdzą się studnie betonowe, które można wyposażyć w schodki wewnętrzne

–niezłazowe (inspekcyjne) – posiadają o wiele mniejsze średnice od studzienek złazowych, dlatego pozwalają one jedynie zajrzeć do środka. Zakres prac, jakie można w nich przeprowadzić odpowiada odległości, na jaką jest w stanie sięgnąć człowiek. Gdy nie ma konieczności zamontowania schodków złazowych, idealnym rozwiązaniem są właśnie studzienki z tworzywa sztucznego.

Różnice pomiędzy studnią betonową a tworzywową?

Największą różnicą pomiędzy studzienkami z betonu, a z tworzywa sztucznego jest ich waga. Studnie betonowe, choć wydają się bardzo solidne, to posiadają wiele wad. Studzienki z tworzywa są lekkie i proste w montażu. Natomiast studzienki betonowe wymagają użycia specjalistycznego sprzętu, co znacznie wydłuża czas instalacji i podnosi koszty inwestycji.

Studzienki z tworzyw sztucznych są odporne na wszelkie związki chemiczne. W studniach betonowych występuje tzw. korozja siarczanowa, co wpływa na ich trwałość.

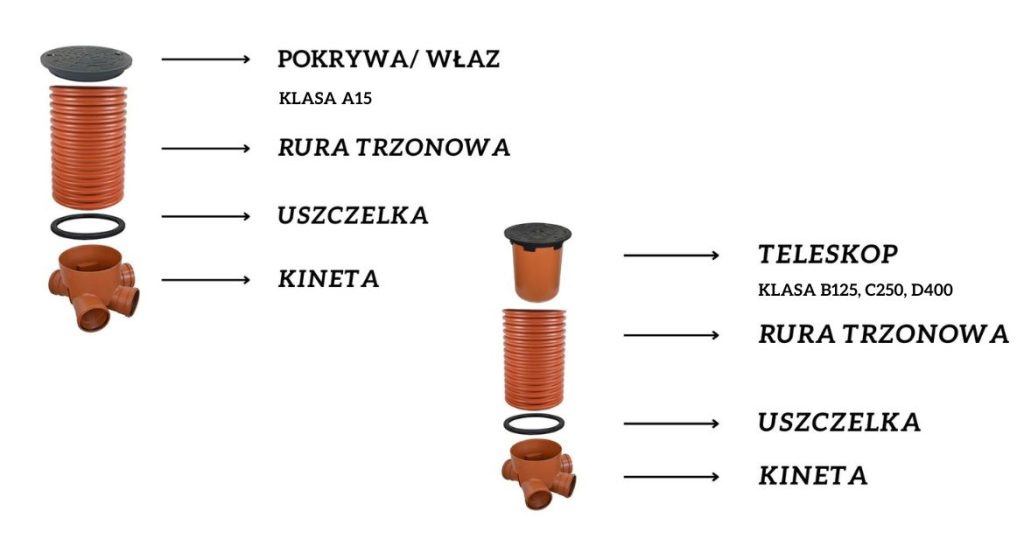

Budowa studzienki z tworzywa sztucznego.

Podstawowym elementem tworzywowej studzienki jest rura karbowana trzonowa. Posiada karby, pomiędzy które podczas zakopywania dostaje się ziemia. Dobrze przygotowane podłoże ma na celu ochronę przed osiadaniem się gruntu wokół studzienki. Długość rury uzależniona jest od głębokości budowanej studzienki.

Kolejnym istotnym elementem studzienki jest kineta. Podstawa studni wyposażona jest w przyłącza dla rur kanalizacyjnych przepływowych oraz gniazda głównego dla rury karbowanej.

W zależności od ilości przyłączy wyróżniamy kinety:

–przelotowe– posiadają dwa króćce zakończone kielichem

–zbiorcze– posiadają kilka króćców zakończonych kielichem

–przelotowe z dolotem prawym lub lewym– posiadają dwa króćce plus jeden

U zwieńczenia studzienki należy zamontować właz lub pokrywę. Jeżeli studzienka budowana jest w miejscu ruchu pieszo-rowerowego, wystarczy zamontować właz o klasie A15. Jeżeli jednak nad studzienką będzie odbywał się ruch aut, należy zastosować właz B125, C250 lub D400. Przy wyższych klasach obciążenia konieczne jest zamontowanie teleskopu, który ma za zadanie wyeliminowanie obciążeń działających na podstawę studni.

Podsumowanie:

Studzienka to ważny element sieci kanalizacyjnej. Umożliwia dostęp do instalacji w przypadku awarii. Zarówno betonowe, jak i tworzywowe studzienki cieszą się dużą popularnością. Gdy nie ma możliwości użycia specjalistycznego sprzętu, zalecana jest budowa studni z tworzywa sztucznego. Na rynku dostępnych jest wiele modeli kinet oraz włazów pasujących do konkretnych średnic studzienek.