Decydując się na ogrzewanie domu gazem ziemnym musimy wykonać instalację gazową z wysokiej jakości materiałów, oraz szafkę gazową z osprzętem, który pozwoli nam bezpiecznie podłączyć nasz budynek do sieci gazowej. A o tym jak zabezpieczyć instalacje dowiecie się z artykułu.

W poniższym wpisie zagłębimy się w wyposażenie szafki gazowej w której wchodzą: urządzenia pomiarowe, odcinające oraz zabezpieczające wewnętrzną instalację gazową – czym są i jak działają?

Gazomierz miechowy

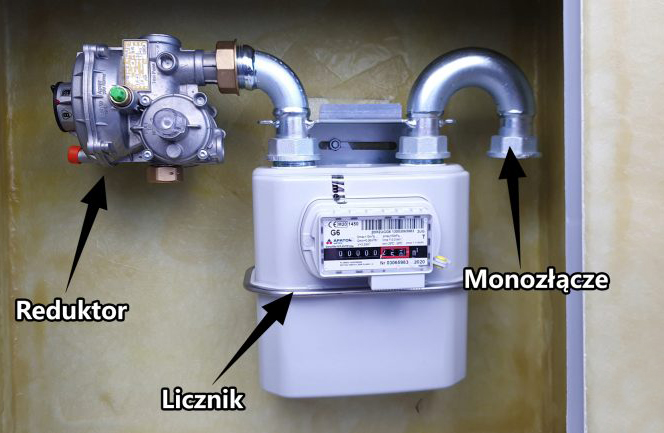

Głównym elementem wyposażenia szafki gazowej jest gazomierz. W instalacjach domowych stosuje się gazomierze miechowe, które mocuje się za pomocą monozłącza. Monozłącza stanowią również ważne wyposażenie skrzynki gazowej. Istnieją różne rodzaje monozłączy. Różnice wynikają na przykład z lokalizacji danego województwa. Są monozłącza do niskiego, średniego oraz wysokiego ciśnienia. Zazwyczaj rury gazowe mają średnie ciśnienie. I tak na przykład: przy średnim ciśnieniu złącze gwintowane używamy w większej części Polski. Złącza kołnierzowe są stosowane są głównie na Dolnym Śląsku. Pamiętajmy, że w projekcie Pozostałe parametry takie jak rozstaw pod gazomierz powinny być zawarte w projekcie.

Reduktory ciśnienia

W szafkach gazowych obowiązkowo musi znaleźć się reduktor ciśnienia. Dostosowuje on ciśnienie przepływającego gazu z sieci do ciśnienia w wewnętrznej instalacji gazowej. Dla instalacji domowej przeznaczone są reduktory dwustopniowe – mogą być one proste lub zakrzywione.

Na wyposażeniu każdego reduktora znajdziemy :

- korpus

- przeponę regulacyjną

- mechanizmy wykonawcze

- zawory dławiące

- korpusy tłumiące drgania

Reduktory gazu charakteryzują się wymaganym ciśnieniem wlotowym maksymalnym i minimalnym , oraz przepustowością maksymalną przy minimalnym ciśnieniu wlotowym.

Szafka gazowa

Co najważniejsze przyłącze gazowe jest na wyposażeniu każdej szafki gazowej. Jednak ze względu na sposób montażu możemy wyróżnić następujące rodzaje szafek gazowych :

- wnękowe – montowane we wnęce ściennej w specjalnej osłonie z profilem,

- wolnostojące – najczęściej montowane na słupkach lub montowana w ogrodzeniu,

- naścienne – montowana bezpośrednio na ścianie budynku, pozbawiona tylnej ścianki,

- podtynkowe – obudowa do montażu we wnęce, na zewnątrz widoczne są jedynie drzwi skrzynki

Z uwagi na materiał, z którego są wykonane, wyróżniamy szafki:

- plastikowe – najczęściej stosowana w domach jednorodzinnych, przystosowane do montażu z linii ogrodzenia, we wnękach ściennych lub do pozostawienia jako wolnostojąca,

- metalowe – wykonane ze stali kwasoodpornej, która charakteryzuje się bardzo wysoką odpornością. Chcąc uzyskać maksymalną ochronę, szafkę można pokryć zabezpieczeniem antykorozyjnym, jak np. szafkę gazowa nierdzewna

W naszej ofercie znajdą Państwo wiele wariantów skrzynek gazowych, oraz zestawy przyłącza gazu płynnego z reduktorem i skrzynką. Co więcej, o tym czy skrzynka gazowa musi być żółta mówiliśmy w naszym filmiku.

Kurek gazowy

Przede wszystkim w szafce gazowej znajdziemy również kurek gazowy, który umożliwia odcięcie dopływu gazu w sytuacjach awaryjnych lub na czas remontu instalacji. Ponadto zgodnie z przepisami kurek główny montuję się co najmniej 0,5 m od poziomu terenu oraz najmniej 0,5 m od najbliższej krawędzi okna, drzwi lub innego otworu umożliwiającego swobodne dojście.

Jednak pamietajmy, iż ze względów bezpieczeństwa liczników gazowych i elektrycznych nie montujemy we wspólnych wnękach, skrzynka gazowa jest zakładamy w odległości co najmniej metra od skrzynki elektrycznej.

Podsumowując co najważniejsze, decydując się na ogrzewanie domu gazem ziemnym pamiętajmy aby wykonać instalację gazową z wysokiej jakości materiałów, które pozwolą nam bezpiecznie podłączyć nasz budynek do sieci gazowej.