Nowadays, pipes made of polyethylene are becoming increasingly popular. They are used for sanitary, water supply and even gas installations. One of the most effective methods of joining pipes is electrofusion welding. In the following article, we show you step-by-step how to prepare for it in order to perform it correctly.

What is electrofusion welding?

Electrofusion welding is a method of joining polyethylene pipes using special fittings that are equipped with built-in heating elements. Electrofusion welding is only carried out under specific conditions. Proper preparation of the welding site is also very important.

Electrofusion welding step by step:

1One of the most important elements of electrofusion welding is that the pipes to be electrofusion welded are cut at right angles and are properly cleaned with a scraper

2. The next step will be to remove the oxidised layer of polyethylene at the welding point. In order for this to take place at the correct length, measurements need to be taken. Each electrofusion fitting has correspondingly long cold zones outside and inside the electrofusion wire. We measure this length and then measure from the edge of the pipe the area to be scraped and mark it with a pen so that the whole is scraped thoroughly.

3The scraped pipe should be properly degreased by means of a wipes . It is also a good idea to degrease the electrofusion fitting. Pipe and fitting are joined together. Remember that the parts to be joined must be absolutely dry.

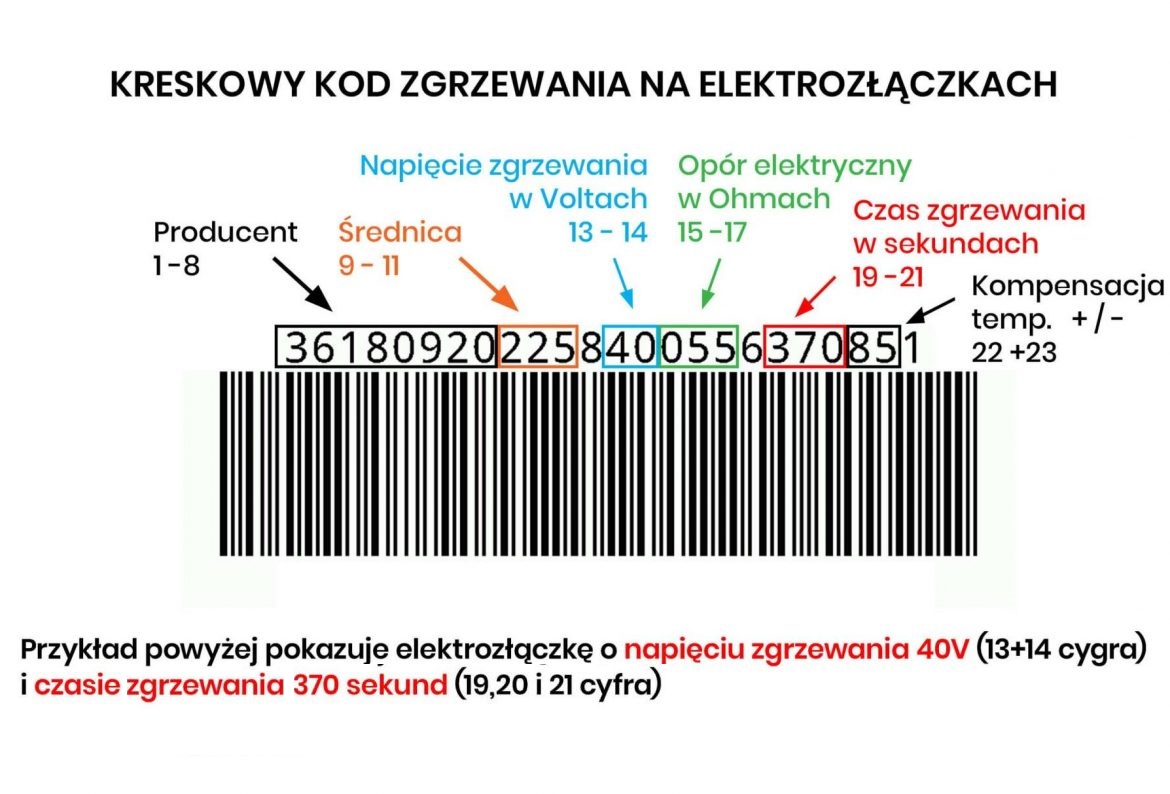

4We proceed to welding. Switch on welderthen connect the ends of the welding machine and remove the mini scanner to scan the code, and read out all the moulding information on the machine's display. However, in the event of a scanner malfunction or other unforeseen situations, these parameters must be entered manually. All the information necessary for entry is also contained in the code of the shapers, as shown in the attached drawing.

5. Confirm the selected settings and the welding process begins. A control bar appears on the display of the sealing machine to inform us of the sealing status. The device saves the sealing process.

6The cooling time is indicated on each shape by the CT symbol. The cap shown will be able to be moved after 7 minutes. The fittings have control tabs in the form of indicators that pop up during the cooling phase.

Electrofusion welding of PE pipes is relatively simple to perform. However, in order for it to be performed correctly and for the pipe connections to be durable, we need to keep in mind a few important aspects, such as temperature and other weather factors, proper preparation of pipes and fittings for welding, and the proper execution of the electrofusion welding itself. Also worth reading article on other ways of joining pipes.

We also have a range of other welding accessories. You will find ballooning adapters, cleaning wipes, fittings, steel flange connections, saddle mounting jigs, drilling tools, centrators, among others.

All our products are characterised by:

- high quality workmanship, durability and attention to the highest safety standards

- a design ensuring not only functionality but also ease and comfort of use

- production in companies experienced in producing parts and accessories for welding

We encourage you to purchase the welding range and believe you will find the equipment you need and be extremely satisfied after purchase and during use.